Preheat Heat Treatment Services in Pipes and Pressure Vessels: Optimizing Weld Quality.

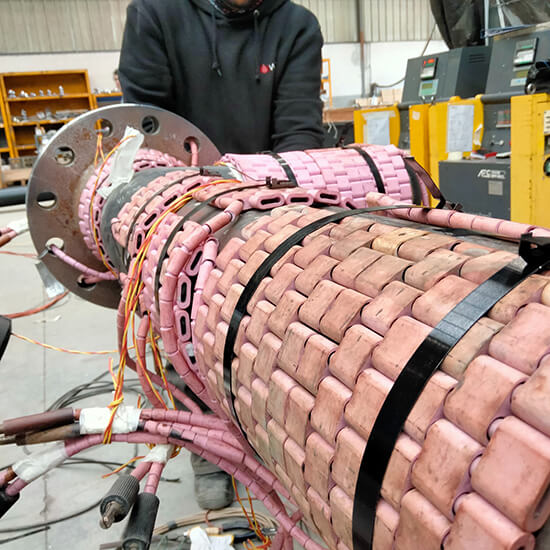

Preheat heat treatment is a crucial pre-welding process employed in the fabrication of pipes and pressure vessels, particularly those made from thicker sections or materials susceptible to cracking. It involves heating the base material to a specific temperature before welding commences. This controlled preheating significantly improves the weld quality and reduces the risk of weld defects.

The process involves raising the temperature of the base material in the surrounding area of the weld joint to a predetermined level. This temperature is maintained throughout the welding process and for a short period afterward. The specific preheat temperature depends on several factors, including the base material's thickness, type, and susceptibility to cracking, as well as the welding process used. Our Procedures and relevant codes and standards (e.g., ASME Section IX, EN 1011-2) provide guidelines for determining the appropriate preheat temperature.

Reduced Weld Cracking: Preheat reduces the cooling rate of the weld, preventing the formation of hard, brittle zones (heat-affected zones or HAZ) that are prone to cracking. This is particularly important for materials with high carbon content or low ductility.

Improved Weld Metal Properties: By slowing down the cooling rate, preheat allows better grain refinement in the weld metal, resulting in improved mechanical properties such as ductility, toughness, and impact strength.

Reduced Distortion: Preheat helps to minimize distortion and warping during welding, leading to improved dimensional accuracy and reduced post-weld finishing requirements.

Enhanced Penetration: In some cases, preheat can improve weld penetration, ensuring a complete fusion between the base material and the weld metal.

Improved Hydrogen Control: Preheat can help to reduce the amount of hydrogen absorbed by the weld metal, minimizing the risk of hydrogen-induced cracking.

Increased Weldability: By reducing the cooling rate and improving the microstructure, preheat enhances the weldability of the base material, making it easier to achieve high-quality welds.