Power Plants

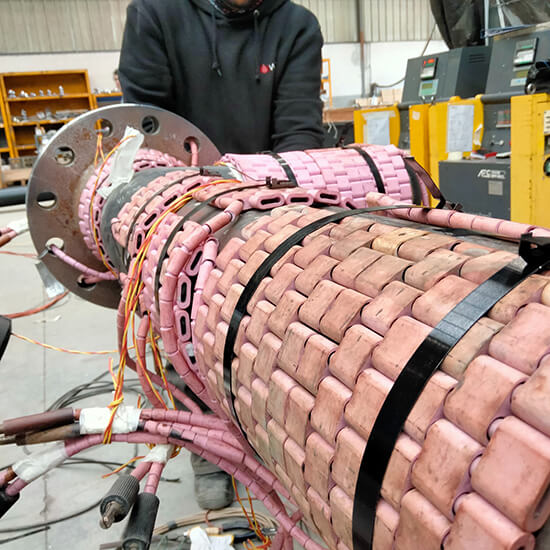

Post Weld Heat Treatment

Improves the weld microstructure, reducing residual stresses to extend the life of vessels, pressure tanks, and equipment. Our global service covers industries like construction, offshore platforms, and petrochemicals. Using advanced thermal calculations and adhering to welding codes, we offer both on-site and factory PWHT with full.

Read more about post weld heat treatment

Preheating

Preheating is the process of raising the temperature of the base metal before welding or cutting to reduce the risk of cracking and improve weld quality. It ensures uniform expansion, minimizes thermal stress, and enhances the metallurgical properties of the material, making it crucial for hydrocarbon-related applications.

Read more about post weld heat treatment

Bolt and Torque

Bolt and torque services involve precision tightening and tensioning of fasteners to ensure structural integrity and prevent leaks in high-pressure and high-temperature hydrocarbon systems. Proper bolting techniques help maintain joint integrity, reduce maintenance costs, and improve safety in pipelines, refineries, and petrochemical plants.

Read more about post weld heat treatment

Cold cut and weld-prep

Cold cutting and weld preparation services provide precise and safe cutting of pipes and metal structures without generating heat-affected zones. This method is essential for power plants industries where sparks or high temperatures can pose a safety risk. It ensures clean, burr-free cuts, making subsequent welding processes more efficient and reliable.

Read more about post weld heat treatment

Engineering Service

Our engineering services support

power plants industries with customized solutions, including design, analysis, and optimization of equipment and processes. We offer technical expertise in plant maintenance, infrastructure development, and efficiency improvements to enhance operational safety, reliability, and compliance with industry standards.

Dry out of refractory lining

Dry-out ensures the safe removal of moisture from newly installed refractory linings, preventing cracking or spalling due to thermal stress. This process enhances the durability and performance of linings in high-temperature areas like kilns and preheaters.

Read more about furnace dry out and heat up