YOUR BEST SOLUTION PARTNER

Explore Our Industries And Services

Postweld Heat Treatment

We have in our installations furnaces to post weld heat treating of large vessel pressures or vesse.

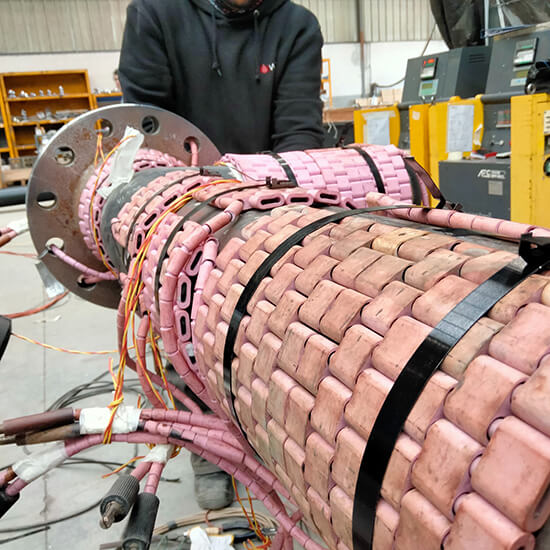

Electrical Heat Treatment

Enhancing durability and performance of refractory linings for industrial furnaces.

Heat Band Simulation Using FEA

Finite Element Analysis (FEA) models thermal stress distribution in a heat band

capturing the effects of temperature gradients and material expansion.

Mechanical Services

Pipe Cutting, Beveling & Bolt Torque Tailored solutions to optimize industrial processes and infrastructure.

We Love It Hot

Explore Our Industries And Services

Postweld Heat Treatment

We have in our installations furnaces to post weld heat treating of large vessel pressures or vesse.

Welding Preheat & Hydrogen Bake-Out

Preventing weld cracking and improving metallurgical properties.

Electrical Heat Treatment

Enhancing durability and performance of refractory linings for industrial furnaces.

Heat Band Simulation Using FEA

Finite Element Analysis (FEA) models thermal stress distribution in a heat bandcapturing the effects of temperature gradients and material expansion.

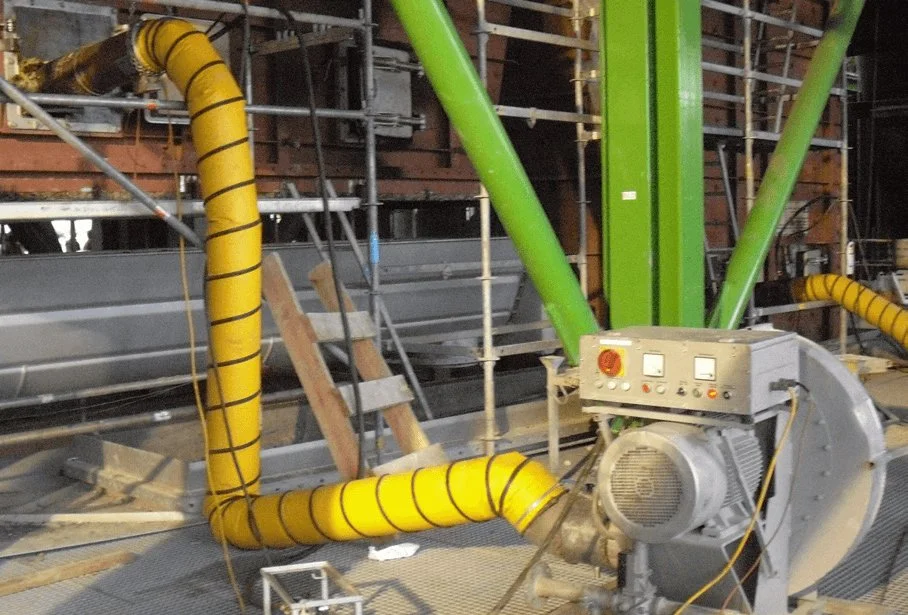

Refractory Lining Dry Out

On-site machining for accurate and efficient equipment maintenance.

Mechanical Services

Pipe Cutting, Beveling & Bolt Torque Tailored solutions to optimize industrial processes and infrastructure.

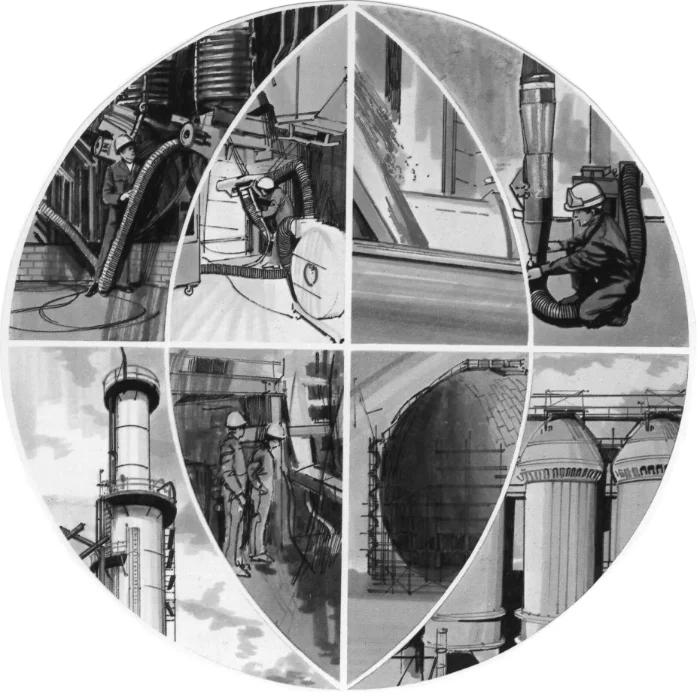

WHO WE ARE

Hotwork Heat Treatment & Specialized Services (HTS), a proud member of the Hotwork International Group, is a global leader in heat treatment, combustion services, and industrial thermal solutions. With a heritage dating back to 1962, HTS has earned a reputation as a trusted provider for industries such as glass manufacturing, aluminum production, copper processing, and the oil & gas sector.

At HTS, we specialize in thermal treatment solutions that enhance weld integrity, minimize thermal stress, and extend the operational life of pressure vessels, storage tanks, pipelines, and industrial towers. Our expert engineering team leverages advanced analytical tools, including thermal simulations, wind and weight load calculations, and Zick analysis for horizontal vessel support optimization.

Since joining the Hotwork International Group in 2022, HTS has expanded its global footprint and technical capabilities. With a network of over 600 specialized technicians and engineers, we provide heat treatment services in more than 65 countries, ensuring a 48-hour global response time and consistent service excellence.

HTS began its journey with the establishment of Heat Treatment and Specialized Services Portugal, offering robust coverage across Southern Europe. In 2025, we further expanded with the launch of HTS Netherlands, strategically enhancing our responsiveness and presence throughout Western and Northern Europe.

WHAT WE DO

Post Weld Heat Treatment

Ensuring the strength and durability of welded components, our Post Weld Heat Treatment (PWHT) service relieves residual stress, improves material properties, and prevents cracking in welded structures. This process enhances the longevity and performance of industrial equipment.

Read more...

Welding Preheat / Hydrogen Bake Out

Our Welding Preheat and Hydrogen Bake Out services reduce the risk of weld failure by controlling temperature during and after welding. Preheating minimizes thermal stress, while hydrogen bake-out removes trapped hydrogen, preventing weld cracking and ensuring structural integrity.

Read more...

Refractory Dry-Out

We specialize in Refractory Dry Out, a critical process for curing and strengthening refractory linings in furnaces, kilns, and industrial vessels. Our controlled heating procedures prevent thermal shock, moisture retention, and premature failure, ensuring long-lasting refractory performance.

Read more...Featured Services

Our Services:

- Post Weld Heat Treatment

- Pre-Heating

- Hydrogen Bake Out

- Dry Out

- Engineering

- Sales and Rental

- Cold cut and Beveling

Our Equipments

- 50 kVA

- 35 kW Unit

- HV-1500

- HV-3000

- HVO-3600

Our Industries

- Refineries

- Petrochemical

- Steel

- Hydrocarbon

- Power Plant

- Shipyards \ Constructions

Siep Klok

Siep Klok Ilja Van Buuren

Ilja Van Buuren Wijnand van Buuren

Wijnand van Buuren